Product Details

Professional supply of high-quality refractory clay crucible

Clay refractory crucibles for fire assay are made with fire clay and proprietary additives and has more than 3000 years history in both historical texts and gold refining industry. A cruicible is, in simple term, a ceramic cup. So it is also called pot.

A modern fire assay clay pot is not so far removed from those of the past with the exception of the additional science and technology behind its compositions. Modern fire assay crucibles or orientation crucibles are designed and manufactured for mineral and geochemical laboratories’ usage rather than refining and so are required to be exacting in their specifications and strong enough to withstand huge changes in temperature through multiple uses.

Different from offering one shot disposable crucible, Qingdao Decent Group produce and provide fire assay clay crucibles which have well-deserved reputation for multiple firings uses. Our standard range of fire assay clay crucibles from 30g to 65g can usually be proceeded 5-times-firing and sometimes can be even repeatedly used in more than 9 times with some formula of flux. This feature provides our customers important benefits of reducing cost per firing and increasing profitability. And we can also design and supply to our customer's individual requirements and specifications in dimensions, shape and so on.

[ Professional Production ]

We have more than 20 years experiences in the industrial ceramic and refractory industry, including fire assay crucible, cupel and so on. Our current factory plant of industrial ceramic and refractory products is around 30,000 square meters (around 8 acres) which includes one office building, three production workshops and one warehouse. Our current annual production capacity of crucible is 6.5 million pieces and can be expanded to more than 9 million if necessary.

We supply high quality fire assay multi-firing clay crucibles with the latest automated technology and so we can guarantee sizing consistency which is critical for multi-pour systems and automated lines in fire assay laboratories. Meanwhile, carefully selected raw materials and more reasonable formulation with low caustic soda, low iron content and high silicon content enable our fire assay crucibles withstand 1650 degree thermal shock.

The crucible ingredients are as the below

| Ingredients | Percentage |

|

Silica (SiO2) |

60%-65% |

|

Magnesium Oxide |

<0.2% |

|

Calcium Oxide |

<0.6% |

|

Aluminum Oxide |

30%-34% |

|

Ferric Oxide |

<2% |

|

Titanium Oxide |

<2% |

|

Sodium Oxide |

<0.1% |

|

Potassium Oxide |

<0.5% |

What's more, we are the only manufacturer in China which has complete in-house capability for all production processes of fire assay clay pots. This ensures best control in quality, cost and order lead time from the beginning of production. So we keep supplying multiple firing fire assay clay pots to many well-known fire assay laboratories in all over the world. Below are some photos of production procedure and process.

[ Customization ]

Customization is also available for any requirement to shape, size and so on. We can even mold logo, model no. or other signs onto the bottom of crucible if it is required by customer.

[ Quality Control ]

We have very strict quality control and inspection procedure and standard to every batch of crucibles. Following process is applied to all batches of pots.

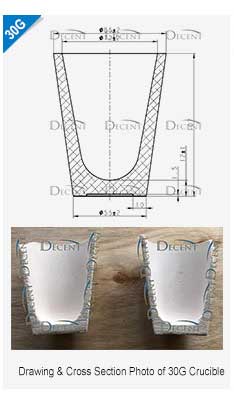

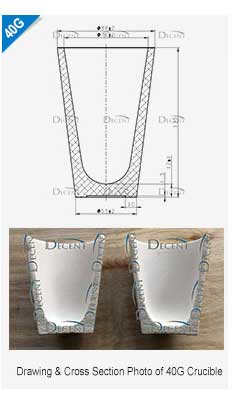

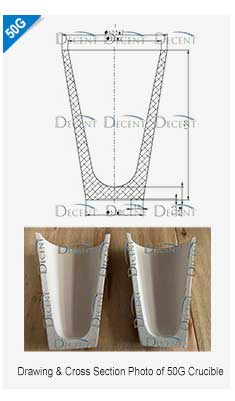

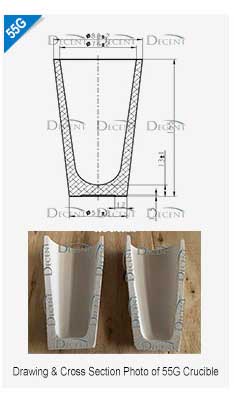

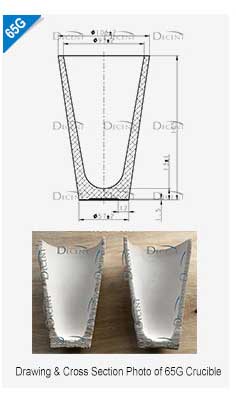

Visual Check & Inspection: Fire assay clay pots are randomly selected from crates package according to sampling rate. All randomly selected pots are weighed to check weight variability. Then the durability of pots is tested by striking the pots increasingly harder. After these tests, the randomly selected fire assay clay pots are cut in half to provide a cross section, which enables QC to check the consistency of grain size and external profile in height and width.

Use Test: Randomly selecting some pots again according to sampling rate and then adding flux without silica in pots to ensure the pots are tested aggressively. Then placing these crucibles into fusion furnace which has been set at 1050°C for 1 hour to replicate normal fusion conditions. This process is repeated in 5 times. The final test result can be recorded as Pass if no noticeable difference in pouring is observed among the pots and no lead splashing on the moulds occurred and no any structural damage, i.e. cracks or holes in the walls, to the crucibles.

Replicate Normal Fusion Conditions for Use Test Crucible Status after 5 Times Firing

Above photo is the status of our fire assay clay crucibles after 5 fires which has no any structural damage (Borax constituent of flux attacks material of crucible and can cause structural defects) and no any showed signs of being compromised i.e. cracks or holes in the crucible walls. From the photo we can notice that the crucible walls are less eroded and still appear smooth appearance. All these approve the premium quality and multiple firings feature of Decent crucible.

Boil Over Status after 5 Times Firing

Above photo shows the boil over status of our clay crucibles after 5 fires, which show less evidence of boil over and also approves the premium quality and excellent multi-trip feature of Decent fire assay clay crucibles.

[ Package ]

[ Delivery Time ]

We keep stock for almost all models of crucible in the warehouses at both our production facility and Qingdao port for various consignment deliveries requirements to any location around the world. The shortest order lead time and delivery time can be 3 days after receiving order confirmation, which ensures on time and in full delivery for any urgent order.

[ Container Loading ]We ship hundreds of containers of crucibles to all over the world. So we have rich experience for container loading to meet various requirements to FCL shipment such as followings:

The fire assay crucible is a necessary vessel in the process of analyzing precious metals by fire assay. The fire test method is an ancient and legendary method. For over 3000 years, due to its accuracy in fire assay the content of gold, this method is still the most important test method. The fire assay method is generally divided into three steps:

1. Melting

Crucibles with fire assay flux and the sample is put into the fusion furnace. The lead captures the gold, silver and precious metals in the molten state to form a lead alloy (generally called a lead button). The lead alloy due to the high specificity sink to the bottom of the crucible. The base metal oxides and gangue react with fluxes (silica, borax, and sodium carbonate) to form slags (silicate or borate). Slags floats on the crucible due to its small specific gravity. So the gold and silver separate from the sample.

2. Cupellation

Put the obtained lead alloy in a cupel at an appropriate temperature to remove lead. During cupellation, the lead is oxidized to lead oxide and penetrates into the porous ashtray. Thereby removing the lead in the lead button and a small amount of base metal. Gold silver and precious metals are not oxidized and remain in the cupel to form gold and silver particles.

3. Partition

Use nitric acid to dissolve the gold-silver composite particles to dissolve the silver while the gold remains solid. The obtained gold particles are weighed after quenching, and the gold content can be calculated. The silver content can be calculated based on the difference between the quality of the gold-silver composite particles and the gold quality.

[ Technical Parameters ]

Besides the models and dimensions of fire assay clay pots listed below, we are also able to produce any model and size of fire assay clay pots according to customer's requirements.

|

Model No. |

Top OD (mm) |

Base OD (mm) |

Height (mm) |

Pcs/Crate |

Crate /20' Container |

|

DCC20 |

76 |

46 |

98 |

3000 |

20 |

|

DCC30 |

85 |

56 |

105 |

2574 |

20 |

|

DCC40 |

90 |

56 |

135 |

2000 |

20 |

|

DCC50 |

105 |

56 |

150 |

1530 |

20 |

|

DCC55 |

90 |

56 |

155 |

1500 |

20 |

|

DCC65 |

105 |

56 |

165 |

1400 |

20 |

|

DCC75L |

120 |

75 |

160 |

1000 |

20 |

|

DCC75S |

110 |

60 |

200 |

840 |

20 |

|

DCC75I |

125 |

61 |

210 |

672 |

20 |

|

AC1 |

105 |

56 |

130 |

880 |

20 |

|

AC2 |

110 |

70 |

130 |

880 |

20 |

[ Related Products ]

Languages

Languages 中文

中文 English

English Español

Español Pусский

Pусский Deutsch

Deutsch العربية

العربية